Elevating Customer Success: Qv21 Technologies

The Customer-Centric Approach In a world where customer expectations continue to soar, the trucking industry is no exception. Customers seek more...

6 min read

Fallon Judd

:

6/18/21 8:05 AM

Fallon Judd

:

6/18/21 8:05 AM

While most of us are familiar with the frequently cited benefits of proper solid waste, the purpose of any waste management plan is to ensure the proper collection, transportation and disposal of all types of waste, from municipal to industrial, hazardous or non-hazardous. The plan should help you identify where your waste hauling business is now, what your waste-hauling goals are, the specific steps you need to take to reach your goals, and a way to track your fleet and measure your progress towards meeting those goals.

But what details do you need to include in your plan and how do you go about implementing the plan in your waste hauling business? What does the future of waste management look like and what role is Qv21 taking in helping shape that future? We’ll answer all of these questions in this comprehensive guide to creating your own waste management plan.

When talking about the benefits of a proper solid waste management plan, you’ll often hear about the conservation of natural resources, reduced pollution, greater economic development opportunities and improved physical health. While these are obviously great outcomes, as a waste hauler, what kind of business benefits can you and your customers expect from a well-designed waste management plan?

As with any new business venture, setting the budget for your project is likely going to be your top priority. The budget for your waste management plan should include outlays (like the cost of buying and maintaining each individual truck in your fleet over its lifespan), overhead costs (such as driver and dispatcher training, software), and operating costs (such as fuel, salaries, and vehicle maintenance). Start with your best estimates of types and percentages of waste you’ll be moving, how far you’ll be moving the loads, and all of your fixed and variable expenses.

And don’t forget to plan for the future of your waste hauling business! Expanding your fleet, hiring more dispatchers, upgrading your software or building more transfer stations along your routes all need to be accounted for too, even if you’re not anticipating immediate growth.

If you’re looking for ways to save, be wary of hidden costs, particularly when working with your technology provider. Some providers like to charge for things like “cell service” which can add up quickly. Ensure your fleet of trucks is using the most fuel efficient parts, has regular maintenance schedules, and your drivers are trained in safe, fuel-efficient behaviors.

Source separation is critically important but often overlooked as a cost saving factor as well. If waste materials are not sorted properly, you may end up sending materials to recycling plants that are actually unable to be recycled and need to be transported back to the landfill. Finally, use software (like Qv21!) to optimize your routes and encourage communication between drivers and dispatchers.

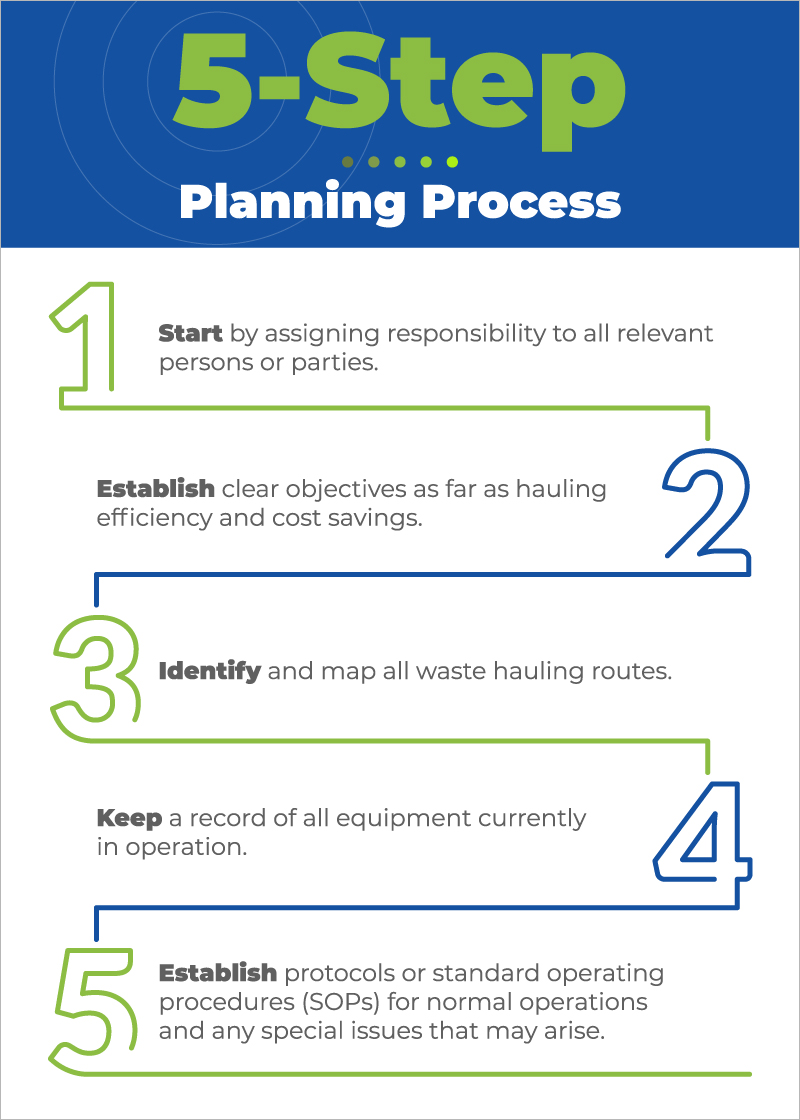

A waste management plan should contain details about who is responsible for what, the types and amounts of waste to be transported, methods and modes of transportation to be used, transportation routes, and safety training and standard operating procedures for all members of your organization.

The infrastructure and equipment required to collect, transfer and dispose of waste is a big investment for any size of waste hauling operation. There are many types of trucks, tanks, trailers and other solid waste transportation methods used to move solid waste:

To optimize your transportation routes, there are a few things you can do right away. First, avoid having your waste hauling routes overlap and try to keep your collection and transport times the same for each route. During collection, prioritize the largest waste-producing sources over the smaller sources to ensure you’re hauling full loads first.

Give all vehicles and solid waste equipment regular cleaning schedules. Finally, use software to help optimize your routes by tracking loads in real-time with GPS, eliminating paper tickets and automating the ticketing process, and giving your dispatchers status updates on your drivers.

From municipal waste to industrial waste, construction debris and biomedical waste, different types of waste must be disposed of properly. Municipal and industrial wastes are two of the largest waste categories and the types that waste haulers most commonly deal with.

Industrial waste is the waste generated from the production of consumer goods, agriculture and mining. Municipal waste, meanwhile, comes from residential and recreational sources and could include things like everyday food, paper and plastic, hazardous household chemicals, electronics, and waste from landscaping.

Hazardous industrial or biomedical waste requires safe disposal in a location sufficiently far away for disposal to occur in an environmentally responsible way. Industrial and construction waste should be stored, transported and disposed of separately from other types of waste.

The United States accounts for over 292 million tons of waste per year -- or 12% of the global municipal waste output. As an industry, waste management continues to grow, with industry-wide annual revenue already exceeding $63 billion dollars. As corporations in every industry around the world are increasingly pressured to adopt more eco-friendly business practices, waste haulers are no exception.

Making sustainable improvements to your waste management business and establishing partnerships with local governments can help you cut costs while also improving the lives of people in both urban and rural environments. To understand the importance of prioritizing more sustainable hauling practices, one just needs to look at a few waste management statistics. Take, for example, 2 metrics commonly tracked by waste haulers: loads per truck per day and deadhead miles.

Loads per truck per day directly impacts your revenue and determines whether or not you’re maximizing your profits as effectively as possible. Deadhead miles -- the distance between one unloading point and your next loading point -- translate into wasted money because these are miles driven with no product. It’s estimated that deadhead miles make up over 35% of all miles driven.

Then, there’s fuel efficiency; data from the US Department of Energy revealed that a typical waste collection truck travels between 20,000 and 30,000 miles every year, consuming over 10,000 gallons of diesel along the way. If you’re not into math, that’s the fuel consumption of approximately 3 miles per gallon. Between minimizing deadhead miles and maximizing the fuel efficiency of your fleet, there are plenty of cost savings to be found in your waste hauling business.

So what can you do to make your business more sustainable?

As a cost-effective, sustainable technology partner to some of the nation’s largest transfer waste transporters, Qv21’s industry-leading transportation management system (TMS) is helping short-haul bulk commodity trucking companies streamline their entire waste collection and transport process. Our core software modules create a more dynamic user experience with greater insights and real-time data:

Qv21's fleet management solution, The LogisticsFramework™ has been helping some of the nation’s largest waste haulers navigate to better insights, greater efficiency and, ultimately, Logistics Without Barriers. For more information, and to get help navigating your own way through the world of fleet logistics, check out our resources page!

The Customer-Centric Approach In a world where customer expectations continue to soar, the trucking industry is no exception. Customers seek more...

Change can be daunting, especially when it involves the adoption of new technology like a Transportation Management System (TMS). While the promise...

In the fast-paced world of logistics and trucking, the landscape is evolving at an unprecedented pace. With technology-driven advancements at the...