Stella Case Study

Synergy & Scalability

The Background

It’s 1992 in Houston, TX.

Stella Environmental Services starts hauling for a humble transfer station, fueled by a vision to serve their future customers in ways that make a memorable and measurable difference.

Fast forward to 2021, and their operation has grown to service over 65 transfer stations across nine states. Stella processes more than seven million tons of waste per year.

Scalability like this doesn’t happen overnight – but it doesn’t take long to start seeing major impacts. When Stella began removing their logistics barriers, everything changed. So, what were the barriers?

The Challenge

In 2018, Stella noticed barriers and pain points arising from inefficient business processes. Drivers' ticket data was captured and collected entirely on handwritten paper tickets, creating room for errors and delays. Operations were monitored and managed on a giant board with Post-It Notes, only waiting for gravity to do its work. There were even employees hired solely to reconcile the mass of paper tickets circulating between departments. Despite it all, Stella was determined to be the premier national transfer station management and logistics services company.

“Truly the inefficiencies of paper and the impact it had on our back-office staff drove us to Qv21,” says Doug Travis, Stella’s Vice President. They were ready to step away from the 90s and into the 21st century.

Our Solution

Stella became a Qv21 customer in 2018 taking their first steps away from the world of paper tickets. Our Onboarding and Customer Experience team reviewed their existing operations to streamline inefficient processes. Our goal: to implement automation from order to invoice.

In order to scale, Stella needed to take on heavier workloads with the same amount of resources in place.

Stella's Scalability with Qv21's TMS, The LogisticsFramework™

Results

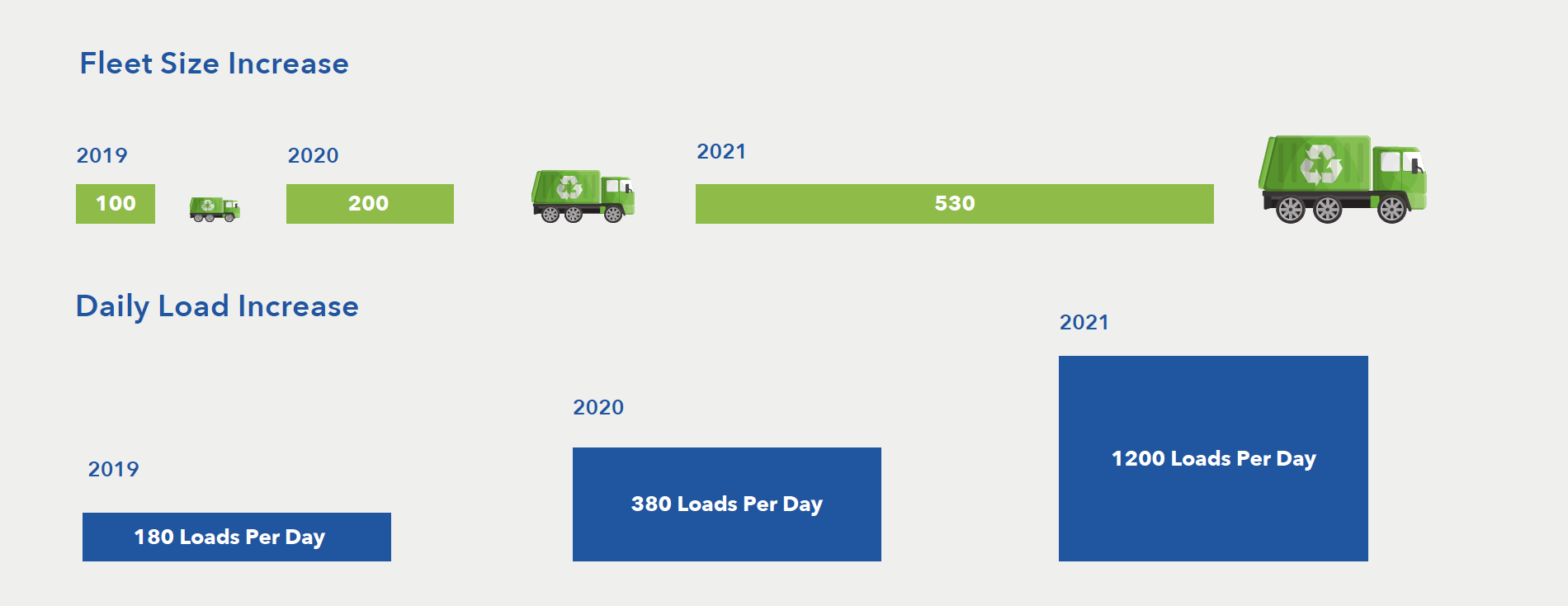

With Qv21's transportation management system (TMS), drivers can turn around loads quicker, and back-office operations can process invoices at a faster rate. By condensing as many as 5-steps into one, Stella's team saw the growth they were looking for.

Qv21’s overall impact was extraordinary, increasing Stella's average daily loads by 65%.

"The scalability with the Qv21 system has really allowed us to be able to step into a market and start day one with little to no issues. TLF provides the capability to begin training our Independent Contractor Drivers a day or two before operations start. Once operations start, we are 100% live and rolling. Before Qv21, drivers would fill out manual tickets and there was, at minimum, a two-day lag on having that paperwork in the office. With Qv21, working on tickets is in real-time. This partnership has greatly set up the back-office side as far as getting the settlement sheets out to the contractors in a timely manner." - Doug Travis, Vice President